Woodworking can be an excellent method for relieving stress and a form of physical exercise. Besides, there are those who do it as a hobby and others do it for business. You can employ woodworking tools to design exceptional furniture that will impress anyone and enhance the beauty of your house as well as the office.

Just like any other job, woodworking is no different and you will be using specific tools. While there are a lot of woodworking tools, you can initially choose the essential ones, and then, as you master the skills, you can add more to them. This article outlines the indispensable woodworking tools you need for all do-it-yourself projects.

19 Must-Have Woodworking Tools For Every DIY Beginner

1. Workbench

It's not technically a tool but an essential item in your DIY projects, as you'll need a location to place your planks for clamps. Sometimes you must place the plank on a bench to cut with a saw.

Image Credits: wikipedia.com

So, you can buy a sturdy workbench capable of holding down heavy items and stable enough to withstand shaking while working. And above all, it must have a flat top and be comfortable to ensure you are not straining to bend down.

Now that you've done plenty of research, you can buy and build the needed materials in a few hours, therefore saving you much money. Who knows what will happen? It might attract a person interested in woodworking to want an exact replica. Hence, it will also serve as a promotional tool.

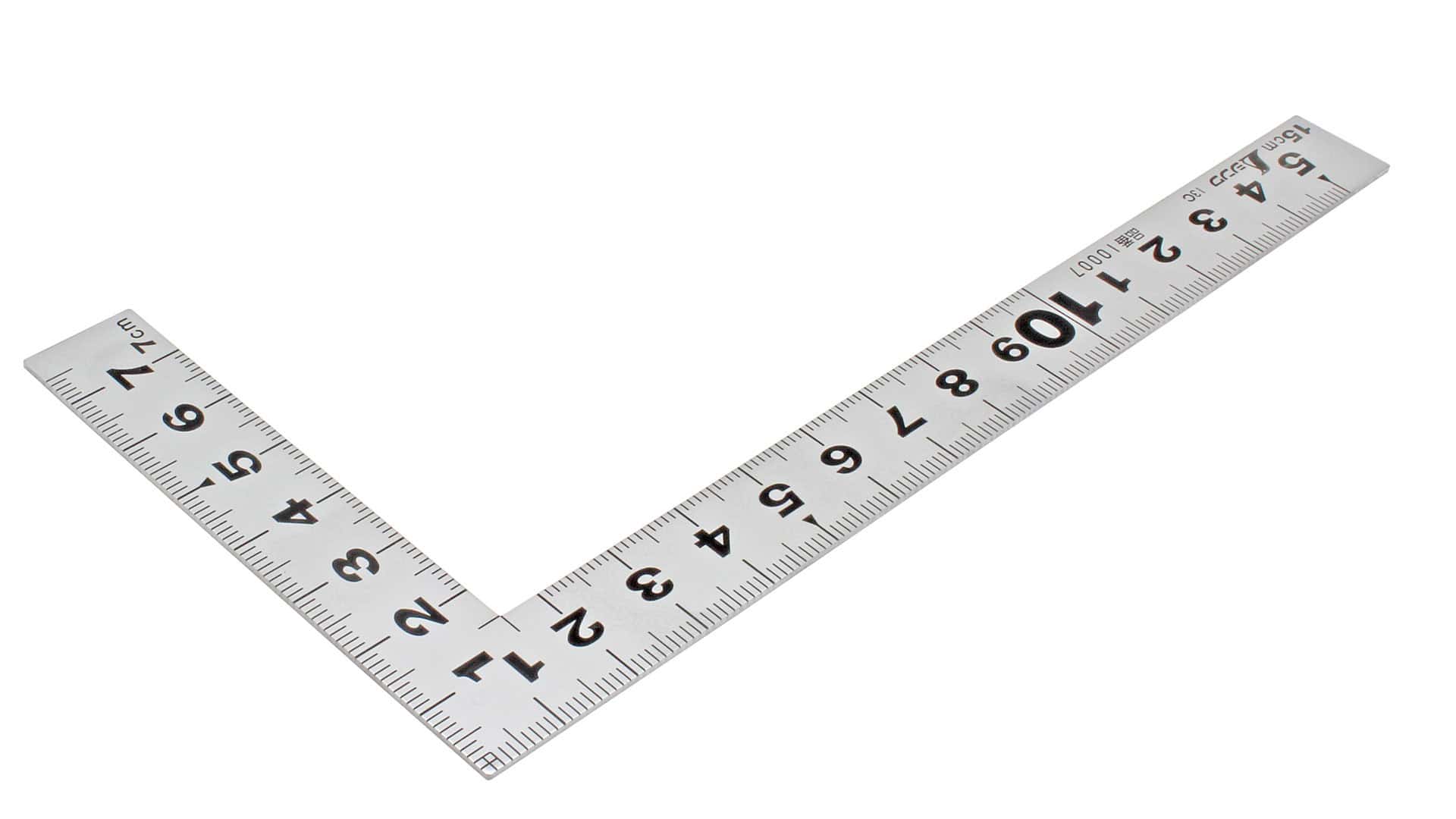

2. Square

Image Credits: finetools.com

If you are building a table, chairs, or cabinets, you must use a square to make sure that the angles you cut are precise. It is one of the tools that comes in different sizes; it is always good to have some variety for different chores. Essential squares include:

- Framing square: Best for big right-angle surfaces

- Try square: Best for small right-angle surfaces

- Speed squares: Measures angles at 90 and 45 degrees

- Miter squares: Best for angled miter cuts

- Bevel Square: Best for recreating an existing angle and transferring the pattern to a new wood surface.

3. Mallet/Hammer

Many need clarification on the two; their designs differ, although they perform similar functions. A hammer has a steel body. On the other hand, a mallet has wooden or leather heads and a detachable handle used to attach various head sizes.

Image Credits: wikipedia

When striking with a hammer, you will feel the striking shock and witness its impression on the surface. But with a mallet, the wood absorbs the shock and leaves minimal marks on the wood surface; thus, it's ideal for tapping wood joints together.

4. Plane

Planes are great for straightening and sanding abrasive wood surfaces. A hand plane has a fixed blade that helps shave off wood fibers, straightening and letting it take up a smoother appeal.

Image Credits: faithfulltools.com

The size of the blade and depth determine how much wood you can shave off. The planes come in different sizes and functions. They include:

- Jack planes can smoothen all surfaces, including straight and curved edges.

- Block planes, which are ideal for small and stour surfaces. They are suitable for smoothening joints.

- Rabbet planes make right-angle grooves along the edges of the wood grain.

- Scraper planes are sometimes called cabinet scrapers, which are suitable for scraping off wood for super-smooth surfaces.

- Joining planes are designed to make smooth edges and join wood pieces together.

- Spokeshaves, which are ideal for smoothening curved surfaces.

5. Lathes

Instead of sticking with the regular square-shaped table and chair legs, some prefer them to have a circular shape. In such a case, you'd need to use a wood lathe to cut, shape and sand the wood into the form you want.

Image Credits: lowes.com

The lathe works by rotating the wooden piece around a stationary cutting tool, which removes all the unwanted parts and gives you a nicely shaped and smooth workpiece.

6. Chisel

This sharp, angled steel blade with a wooden handle is mainly used for carving and cutting wood. When you want very rough wood, you'd have to use it with a mallet to apply force.

Image Credits: wiktionary.org

Chisels vary in shapes, sizes, and styles, and is important to have four to five chisels in your toolbox at a minimum. On the plus side, they are not expensive, and you can buy one for less than $50.

7. Measuring Tape

Every woodworker must have a measuring tape in their toolkit, the most preferred being the 25-foot tape. There are different tape measures, so choose the one that fits your needs.

Image Credits: befr.rs-online.com

- Retractable steel tapes are the most common as they are compact and effortless. Their length ranges from 12-30 feet.

- Flexible reel tapes are made of fabric or steel and are over 100 feet in length.

- Folding rules are rigid and are best for getting accurate measurements. They are folded into sections for storage.

- Yardsticks, also known as rulers and are straight.

8. Sand Block/Random Orbit Sander

When making a table, chair, cabinet, or other wood furniture that requires smooth surfaces, you must use sanding blocks to smooth out the scratches and other things marring the surface. Although labor intensive, it provides the best result. There are rough sanding blocks for working on irregular surfaces, and once it's a bit smooth, you can use a soft sanding block for a super-smooth texture.

Image Credits: thisoldhouse.com

You can invest in a random orbit sander if you have money to spare. It does the work of rough and soft sanding blocks as it helps remove rough scratches on wooden surfaces. And you can adjust the sanding grit to the desired level. It is fast, easy to use, and perfect for small to medium projects.

9. Hand Saw/Portable Table Saw

Hand saws are the most basic woodworking hand tools. They come in various sizes and shapes, with various blade types to suit different accessories and cutting requirements. You'll need saws for cutting your wood.

Image Credits: finetools.com

However, there are different types of saws, each with specific tasks. They include:

- The circular saw has a blade with sharp teeth that cut across the wood. Most circular saws are electric and come in three types of blades. The ripping blade is ideal for cutting the wood along the direction of the grain. Crosscut blade cuts across the grains and a combination of the two. The difference between the blades is in their teeth, as ripping has evenly spaced while crosscut has staggered ones.

- The jigsaw is crucial for every beginner woodworker as they make straight cuts and require you to move it back and forth. It's the most affordable but labor-intensive.

- The table saw is a good investment if you have the budget. It helps make cuts that other saws can't make. The blade is raised above the table and can be adjusted depending on the width of your wood. There are three types of table saws, and they include:

- Cabinet table saws: They are heavy, and their design requires them to stay in one place. They have a cabinet below them where the belt and the blade's pulley system are stored. They are all-purpose and can rip lumber from wood or panel cutting. It is the preferred centerpiece for most workshops.

- Benchtop table saws are light and thus can be placed on a workbench and removed when unused.

- Contractor table saws are primarily used by building contractors as they are fast and easy to use.

- Bandsaws are ideal for making angled or intricately curved cuts.

- Handsaws can be found in every carpenter's workshop. They are affordable, light, easy to use, and make precise cuts.

- Miter saws are best for making angled cuts. And the best part is they are versatile; the blades can be changed to make your preferred cut.

10. Marking Knife

Image Credits: wikipedia.com

Although pencils can make lines on wood, the graphite marks remain on the surface. Avoid marring your wooden surface by using a marking knife for etching clean and accurate lines, especially on woodworking joints like dovetails.

11. Sharpening Tool

Image Credits: woodsmith.com

Since you are working with sharp tools in your workshop, such as planes, saws, and chisels, you must often sharpen them as dull tools slow down your workflow. Invest in the right tool to ensure your tools are always sharp.

12. Drill

Drills are the best power tools for beginners as they are efficient and easy to use. Only a few people still use a hand drill or brace and bit. The best part about having an electric drill is that it's multipurpose, meaning you can attach other tools to transform its function.

Image Credits: nytimes.com

When buying a power drill, go for the corded model with a voltage of 110/120. This is because they have more torque and are more durable than cordless ones.

13. Clamps

To make a table, you must press the wood together compactly to achieve an even and flat surface.

Image Credits: thespruce.com

A clamp will help hold several planks together, allowing you to glue or nail them together. Clamps are available in different types and sizes, and they include:

- Bend clamp

- C-clamp

- Bar clamp

- Pipe clamps.

14. Screw Gun

Image Credits: gambrick.com

You will be working with screws, and instead of struggling with a screwdriver, why not invest in a screw gun. A screw gun makes fastening screws faster and easy to use.

15. Eye And Ear Safety And Gloves

When you are working with different kinds of woodworking tools, you need to think about your safety with the correct eye and ear gear. This will prevent you from being poked by wood splinters in your eyes or ears. Moreover, gloves guard your hand against the sharp tools and against being poked by wood splinters.

16. Toolkit

It is necessary to do regular maintenance on your woodworking tools by cleaning them and keeping them in a quality and spacious tool case.

17. Power Saws

Image Credits: tractorsupply.com

Power saws are powered by electricity or battery and are often used for cutting larger and more demanding jobs. There are circular, jigsaws, bands, and miter saws among the common power saws.

18. Sanders

Sanding can be used for wood smoothing and finishing. They are of different types, namely belts, orbital, and disc types.

19. Routers

Tool size and weight are among the major factors. Heavy tools are more powerful and sturdy, but they can also be challenging to manipulate, especially for newbies. Lighter instruments may be handier, but they might not be as durable as the heavier ones.

Routers are used for shaping and cutting wood. They are especially useful for creating decorative edges and patterns.

Factors To Consider While Choosing Woodworking Tools

A multitude of woodworking tools is present in the market, all with specific features and advantages. These are some factors to consider when choosing woodworking tools:

1. Budget

You have to set a budget before purchasing any woodworking tool. Tools for woodworking can be from quite affordable to very expensive and this will help you reduce the number of choices.

2. Project Requirements

The kind of project you want to carry out will dictate the equipment you require. Different projects need different tools, so it is crucial to select tools that will fit your project.

3. Skill Level

The woodworker's skill level is also an important factor to consider when shopping for woodworking tools. Beginners might need simple, easily operated equipment, while the experienced may need more advanced, professional tools.

4. Quality

Quality is always a primary criterion when shopping for woodworking tools. A higher-quality tool may initially cost more, but it lasts longer and performs better in the long run, making it the cheaper option.

5. Size and Weight

The size and weight of the tools also play a crucial role. Heavier tools may be more durable and stable, but they may also be difficult to handle, especially for beginners. Lighter tools may be easier to handle but may not be as sturdy as heavier tools.

6. Power Source

Woodworking tools can utilize electric or battery power or be manually powered. The type of power source should be considered while selecting tools. Electric tools are more powerful and efficient, requiring less physical effort. On the flip side, hand tools require more effort but give you more control and precision.

7. Safety Features

Safety is the leading concern when working with woodworking tools. Seek tools with the safety features also, such as blade guards, emergency stop switches, and automatic shut-offs.

8. Brand Reputation

Pick tools whose brands are well-known and have a long tradition of manufacturing great instruments. Look for customer ratings and reviews to have an idea about the quality and reliability of the tools.

Frequently Asked Questions On Woodworking Tools For Beginners

1. What tools do you use for woodworking?

There are various tools you can use for woodworking, depending on the specific project you are working on. Here are some common tools to use in woodworking:

- Handsaw

- Power saw

- Planer

- Jointer

- Router

- Chisels

- Drill

- Clamps

- Sandpaper

- Workbench

2. What are the 4 basic skills woodworkers should have?

1. Measuring and Marking

Measuring and marking is one of the most important abilities a woodworker possesses. To measure and mark the wood accurately, different tools, such as tape, combination square, or marking gauge, can be used.

2. Cutting

3. Joinery

The joining of two or more pieces of wood is called joinery. A woodworker should be skilled in different joinery methods including, but not limited to, dovetail joints, mortise and tenon joints and biscuit joints.

4. Finishing

The final step comprises sanding, staining, and applying a coating to protect the wood. A woodwork craftsman needs to know how to sand the wood well, what type of stain to choose and to apply the finish evenly to get a top-notch look.

3. What is the most useful tool for woodworking?

It is an important tool in any woodworking shop and it can be used for different tasks, such as building furniture or making cabinets. It goes without saying that the tool’s utility is relative to the project but for different woodworking projects, others may require a circular saw, a miter saw, or hand planes.

4. What is the most common wood used in woodworking?

Various forms of wood are employed in woodworking, but softwoods are perhaps the most utilized. The softwood family includes coniferous trees such as pine, cedar, and spruce. Softwoods are widely valued in the construction field, woodworking, and furniture-making because of their plentifulness, affordability, and ease of use.

Additionally, hardwoods like oak, maple, and walnut are popular among wood crafters because of their long-lasting qualities as well as their aesthetic appeal, but they are generally more expensive and difficult to work with, compared to softwoods. Alongside these woods, cherry, birch, ash, and mahogany are other favorites in carpentry. Finally, the wood will be determined majorly by the particular project, the appearance that one would want, and the woodworker's inclination and skill.

5. What are the two types of woodworking?

The two main types of woodworking are:

1. Carpentry

Carpentry is woodworking including the work carried out on structures like houses, bridges, and other large buildings. Artisans work with large pieces of wood and employ tools like saws, hammers, and drills to saw, shape and join them together.

2. Fine Woodworking

Experienced woodworking is another term for cabinet making or furniture making which entails creation of furniture pieces that are much smaller and delicate such as tables, chairs, cabinets, and other kinds of decor items.

Specialized woodworkers like to use chisels, planes and routers to design complicated patterns as well as joints which are used to make the wood parts stay in one piece. A wood craftsmanship of this sort usually entails more skill and accuracy than carpentry.