The global use of additive manufacturing, commonly referred to as 3D printing, has raised worries about energy use and environmental effects. While 3D printers provide unique solutions and exciting opportunities, it is critical to study their power consumption to determine their overall sustainability. Our post will look at how much power a common 3D printer uses, what factors influence its energy consumption, and how to maximize energy efficiency.

Let’s get started.

Types of 3D Printers and Their Electricity Usage

There are several varieties of 3D printers on the market, each with its own set of features and power requirements. Here are several typical varieties of 3D printers, along with an outline of their electrical requirements:

1. Fused Deposition Modeling (FDM) Printers

FDM printers are among the most widely used types of 3D printers. They function by extruding melted filament via a nozzle to create items layer by layer. FDM printers typically use less electricity and may operate from an ordinary household electrical socket. The printer’s power consumption normally ranges between 50 and 250 watts, depending on the model and print complexity.

2. Stereolithography (SLA) Printers

Image credit: xometry.eu

SLA printers employ photopolymerization to convert liquid resin into solid things. These printers employ a laser or projector to selectively harden the resin layer by layer. SLA printers sometimes demand more power than FDM printers, ranging from 200 to 500 watts.

3. Digital Light Processing (DLP) Printers

DLP printers are similar to SLA printers because they use photopolymerization to create objects. However, DLP printers use a digital light projector instead of a laser to solidify the resin. DLP printers also tend to have higher electric power consumption in the 200 to 500 watts or more range, similar to SLA printers.

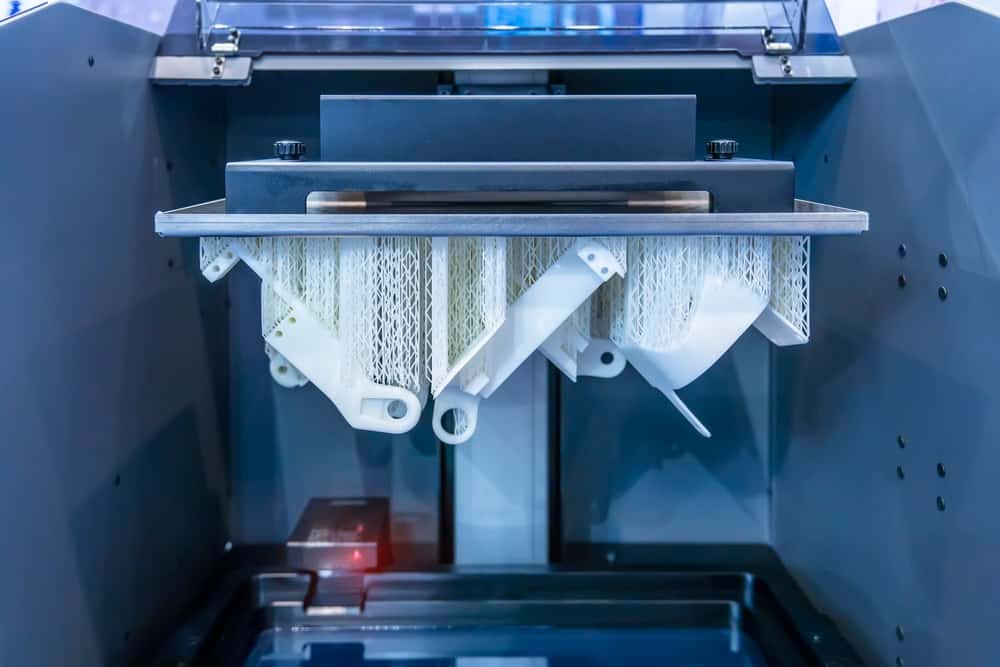

4. Selective Laser Sintering (SLS) Printers

SLS printers employ a powerful laser to selectively fuse powdered materials like nylon or metal into solid shapes. Because of the high energy needs of the laser and the need to heat the print chamber, SLS printers use substantially more electricity than FDM, SLA, or DLP printers. SLS printers’ power usage can range from a few hundred watts to several kilowatts.

5. MultiJet Printing (MJP) Printers

In MJP printers, a printhead deposits droplets of photopolymer onto a build platform, which are subsequently cured layer by layer. These printers, like FDM printers, have modest power requirements, requiring a power source of between 50 to 200 watts.

Image credit: nexamspro.com

How Much Electricity Does a 3D Printer Use?

To determine how much power a 3D printer consumes, consider the printer’s power rating and the time it works. Here’s how to figure out the average power consumption:

1. Determine the Power Rating

To determine the power rating of your 3D printer, consult its specs, a power meter, or the user handbook. It is often expressed in watts (W) or kilowatts (kW). Let us assume the power rating is 500 watts (0.5 kW).

2. Calculate the Energy Consumption per Hour

Multiply the power rating by the number of hours the 3D printer is operational at any one moment. For example, if your 3D printer works for four hours a day, the energy usage per hour would be:

- Energy consumption per hour = Power rating × Operating hours per day

- Energy consumption per hour = 0.5 kW × 4 hours

- Energy consumption per hour = 2 kilowatt-hours (kWh)

3. Determine the Total Energy Consumption

To determine the total power consumption for a certain time period, such as a month, multiply the energy consumption per hour by the total number of hours the printer runs. Assume the printer works for 120 hours each month.

- Total energy consumption = Energy consumption per hour × Operating hours per month

- Total energy consumption = 2 kWh × 120 hours

- Total energy consumption = 240 kilowatt-hours (kWh)

Calculating the Cost of Running a 3D Printer

Image credit: blog.prusa3d.com

To evaluate the cost of operating a 3D printer, you must consider a few factors:

1. Cost of Electricity

To calculate your electricity bills, you must first know how much power your 3D printer consumes and what rate you pay for it. The manufacturer commonly specifies power consumption in watts (W) or kilowatts (kW).

Multiply the power consumption by the number of hours you expect to use the printer, then multiply that by the cost per kilowatt-hour (kWh) to get the electricity cost. For example, if your printer consumes 0.5 kW and you run it for 10 hours at a rate of $0.15 per kWh, the cost would be:

Electricity cost = (0.5 kW 10 hours) $0.15/kWh

2. Cost of Filament or Resin

The cost of filament or resin depends on the type and brand you use. The price is usually specified per kilogram (kg) or litre (L). Additionally, you need to consider the amount of filament or resin consumed per hour by your printer, typically provided in the printer’s specifications.

Multiply the consumption rate by the hours you expect to print, then multiply that by the cost per kilogram or litre to calculate the material cost. For example, if your printer consumes 10 grams of filament per hour and the filament costs $20 per kilogram:

Material cost = (10 grams/hour 10 hours) ($20/kg / 1000 g)

3. Maintenance Costs

Maintenance expenses might include nozzle replacements, bed adhesion materials, and basic printer care. These expenses differ based on the printer model and your usage. Based on the printer’s specifications and your expertise, you should be able to estimate an average monthly or annual maintenance cost.

4. Initial Cost

The initial cost of the 3D printer itself is a one-time expense. This includes the purchase price of the printer and any additional accessories or tools you need to operate it effectively.

Add up the electricity, material, maintenance, and initial costs to get the total cost of running your 3D printer. Remember that these calculations are approximate and may vary depending on your specific circumstances and the details of your 3D printer.

Factors Influencing How Much Electricity a 3D Printer

Several factors can determine how much electricity a 3D printer consumes. Here are some important considerations to consider.

1. Printer Type

Image credit: bitfab.io

Power needs vary depending on the type of 3D printer. Fused Deposition Modeling (FDM) printers, which are popular among hobbyists and enthusiasts, often utilize less power than bigger industrial-grade printers or printers that employ more complicated technologies like as Stereolithography (SLA) or Selective Laser Sintering (SLS).

2. Print Duration

The time it takes to complete a 3D print job affects the total energy consumption. Longer print durations mean more power usage. Larger and more complex objects generally require more time to print, leading to higher energy consumption.

3. Printer Settings

The settings you choose for your 3D printer for cosplay can impact power consumption. Parameters such as print speed, layer height, infill density, and temperature settings can all affect energy usage. Higher speeds or temperatures may require more electricity to operate the printer.

4. Filament Type

The type of filament used in 3D printing might affect power usage. Different filament materials have varied melting temperatures, thus printing with materials that demand higher temperatures may result in greater power consumption.

5. Printer Efficiency

The energy efficiency of the printer itself plays a role in determining its power consumption. More energy-efficient printers, equipped with advanced technologies and optimized designs, can reduce electricity usage compared to older or less efficient models.

6. Idle Time

The energy consumption of a 3D printer may also be influenced by its idle time. Some printers automatically power down or enter standby mode when inactive for a certain period. Others may continue running at a lower power level, consuming less electricity.

7. Additional Features

3D printers may include a heated bed, filament sensors, or LCD panels. These features can cost more power, especially if they are engaged when printing.

8. Power Management Settings

Some 3D printers for architects offer power management settings that allow users to adjust consumption. These settings can include options like reducing motor power or dimming display lights, which can help conserve electricity.

Image credit: phrozen3d.com

Tips on Reducing How Much Energy a 3D Printer

Reducing energy usage is a crucial step toward encouraging sustainability and decreasing the environmental effect of 3D printing. Here are some ideas to help you lower the power usage of your 3D printer:

- Optimize print settings: Reduce the print speed, layer height, and infill density to decrease the time and energy required for printing while maintaining acceptable quality.

- Print smaller and lighter objects: Printing smaller and more delicate objects consumes less material and energy.

- Use energy-efficient equipment: Some printers have energy-saving features like sleep modes or power-off timers, which can help reduce power consumption during idle times.

- Opt for PLA filament: PLA (polylactic acid) filament is a biodegradable and energy-efficient material compared to other heating elements commonly used in 3D printing. PLA has a lower melting temperature, which requires less energy to heat the printer’s extruder.

- Utilize advanced software features: Some 3D printing software offers features like smart tool paths and optimization algorithms. These features help minimize the required support material and optimize the printing paths, reducing energy costs and print time.

- Print in batches: Instead of printing individual objects separately, consider printing multiple objects in a single set. This reduces the number of startup and shutdown cycles, optimizing energy efficiency.

- Maintain your printer: Regularly clean and maintain your 3D printer to ensure it operates efficiently. This includes keeping the print bed clean, lubricating moving parts, and checking for potential issues that could lead to energy wastage.

- Utilize standby and sleep modes: When your printer is not in use, use standby or sleep modes to lower electricity costs. These modes can automatically reduce power usage while preparing the printer for quicker startup.

- Plan prints strategically: Avoid printing objects with excessive support structures or a high likelihood of failure, as these lead to wasted energy and resources.

- Explore alternative technologies: Consider alternative technologies like resin-based 3D printing (SLA or DLP) or selective laser sintering (SLS), depending on your needs. These technologies may offer higher precision and faster printing speeds, reducing energy consumption per printed object.

Frequently Asked Questions on How Much Electricity a 3D Printer Uses

a) Do 3D printers need a lot of electricity?

3D printers typically require considerable amounts of electricity. The power needs vary according to the printer’s size, kind, printing time, and printing substance. Entry-level desktop 3D printers generally consume 50-150 watts per hour, comparable to regular home appliances. However, bigger industrial or commercial versions may require more electricity.

b) Is it expensive to use a 3D printer?

The cost of employing a 3D printer is determined by a number of things. Initially, the cost of a 3D printer might range from a few hundred to several thousand dollars. There are continuing expenditures, such as the cost of 3D printing supplies (filaments or resins), maintenance, and power. However, for smaller projects or amateurs, the overall costs may be affordable.

Conclusion

As 3D printing evolves and expands its uses, knowing how these machines use power becomes critical for sustainable production methods. While 3D printers require power, their energy consumption may be efficiently managed with careful material selection, appropriate print settings, and conscious usage practices. We can achieve a balance between scientific development and environmental responsibility in additive manufacturing by being mindful of power use.