Air compressors have many uses including supplying moderate power to pneumatic tools. Working in a workshop, or small construction company can be challenging without an industrial air compressor. We have included the best 60-gallon air compressors in the sections below.

5 Best 60 Gallon Air Compressors

A 60-gallon air compressor is a perfect beast for working with heavier air tools. Additionally, it is also great for doing heavy tasks at any time. Below is a list of the best air compressors in the market.

1) Ingersoll Rand SS5 5HP 60 Gallon Air Compressor (Single Stage)

- Long-Life: Durable cast iron construction, long-lasting extended...

- Maximum Power and Flexibilty: 100% continuous duty, high pressure...

- Easy Operation: Automatic start/stop pressure switch control,...

- Advanced Safety Features: Manual thermal overload protection of...

- Reliable Operation: All Season Select synthetic lubricant...

This Ingersoll Rand 60-gallon air compressor was made to withstand any environment. It is a 5HP single-stage compressor that is perfect for anything including my small car workshop. Additionally, I have a few DIY auto-painting projects I have undertaken, now that summer is approaching, and this compressor is perfect for the job.

Image Source: lowes.com

Having tested the compressor with a paint gun, and it cut off the air at exactly the required cutoff point, which is 125PSI. The compressor fills itself in less than 3 minutes, and I don't have to stop working as it fills back up. You can also connect it to your older air compressor, and get more than 60 gallons of compressed air.

Keep in mind that the unit doesn't come with a compressor oil lubricant, power cable (you will need a 230v), or pressure regulator. This might seem like a deterrent when you want to purchase a compressor, but keep in mind that you can customize your machine to your specifications. Other than that, this is an excellent piece of equipment, and we might forgive how loud it is, because what compressor isn't?

Pros:

Cons:

2) Quincy QT-54 5 HP Splash Lubrication 60 Gallon Air Compressor

- Industrial-duty US-made Baldor motor

- Capacitor start motor with built-in thermal overload

- Less than 5 PPM oil carry-over (blow-by) rating

- 145-175 working PSI

- Pump RPM: 1310

The first thing that stood out, was how quiet this reciprocating air compressor is. While we expected it to be loud, the low hum was a pleasant surprise. The Baldor motor is a great addition since these motors last for years. Additionally, this single-stage air compressor has perfect air delivery even at maximum pressure.

We tried to run multiple tools on this compressor, and it did not disappoint. The nail gun for roofing and pneumatic saw had the best performances. Additionally, the pump boasts a 30-000 hour pump life, and the CFM rating at maximum pressure is 12.5 PSI. Not to mention, this air compressor has a manual drain system for excess moisture.

The vertical shape of the 60-gallon air compressor is a plus since it's very space-saving. Not to mention, we don't have to worry about accidentally damaging the compressor since it's made of cast iron. Furthermore, this industrial air compressor is very versatile since we can use it on several applications.

Pros:

Cons:

3) NorthStar Electric Air Compressor - 3.7 HP, 60-Gallon Vertical Tank

- Durable cast iron oil-lubricated pump has one-piece cast iron...

- Durable Swedish stainless steel reed valves deliver long service...

- 2-cylinder design for low heat transfer between cylinders

- Heavy-duty 230V induction motor runs at 3,450 RPM for maximum...

- 60-gallon ASME-certified vertical tank provides more air for...

With a working air pressure of 105-135PSI, there is no task that's too large for this air compressor, and it works well with power tools. Like most single-stage air compressors, it has a two-cylinder design that's helpful when we need more pressure when working. Additionally, the CFM rating on 40 and 90 PSI is 11.5. At both pressure levels, this powerful air compressor gives the max air it can give.

With these pressure levels, we were confident that it could handle any job thrown its way. We tried it with the wrench to pry open a lug nut, and it exceeded my expectations.

While we are happy with this purchase, there was one drawback that we didn't expect. Unlike other air compressors, this one takes roughly 7 minutes to fill up. 7 minutes is a long time if you have deadlines to crunch. However, it still works and starts like a charm, but it would be easier if the fill-up time was faster.

Pros:

Cons:

4. Dewalt DXCM603.COM 5 HP 60 Gallon Vertical Air Compressor

By using DEWALT 60 Gallon air compressor, its 14.6 SCFM at 90 PSI flow rate increases tools efficiency for better performance. This made works such as sanding and spraying much easier since we could work with minimal interruptions. The larger 60-gallon tank increases the provision of air for a longer time; thus it is an added advantage for anyone who has big projects.

As for the design, it looks quite sound; it has a powerful induction motor which should be adequate for various voltage grades. However, it is important to adhere to installation process as it demands specific power supply connection. Failing to do so may result in operational problems like those that have been experienced by some of the users.

For the most part, the compressor can be said to work very well, although there is one problem, and that is the noise it emits.

Pros:

Cons:

5. California Air Tools CAT-60040CAD 4.0 HP

We tried the California Air Tools 4.0 HP Ultra Quiet & Oil-Free Air Compressor recently while reviewing air compressors and this was very quiet indeed. It produced sound at only 75 decibels; we realized it is quiet during use, making it ideal for any home or workplace. This is a very far cry from the noisy, cumbersome compressors that we have employed in earlier decades.

The build quality perhaps sets the tone especially taking into consideration the steel 60-gallon tank. It has a seem of solidity and offers sufficient volume of air for our diverse assignments. The twin motors provide good power output and longevity to the unit without cases of severe wearing off as are witnessed in other units. It is also beneficial not to have oil in the design and eliminates putting more effort in the air filter maintenance while giving us clean air once again perfect for our projects.

Pros:

Cons:

Factors to Consider Before Getting an Air Compressor

Getting an air compressor boils down to what you will use it for. However, any compressor worth its name should be able to complete light to moderate tasks without a problem. Here are some factors you should consider before buying an air compressor.

a) Size

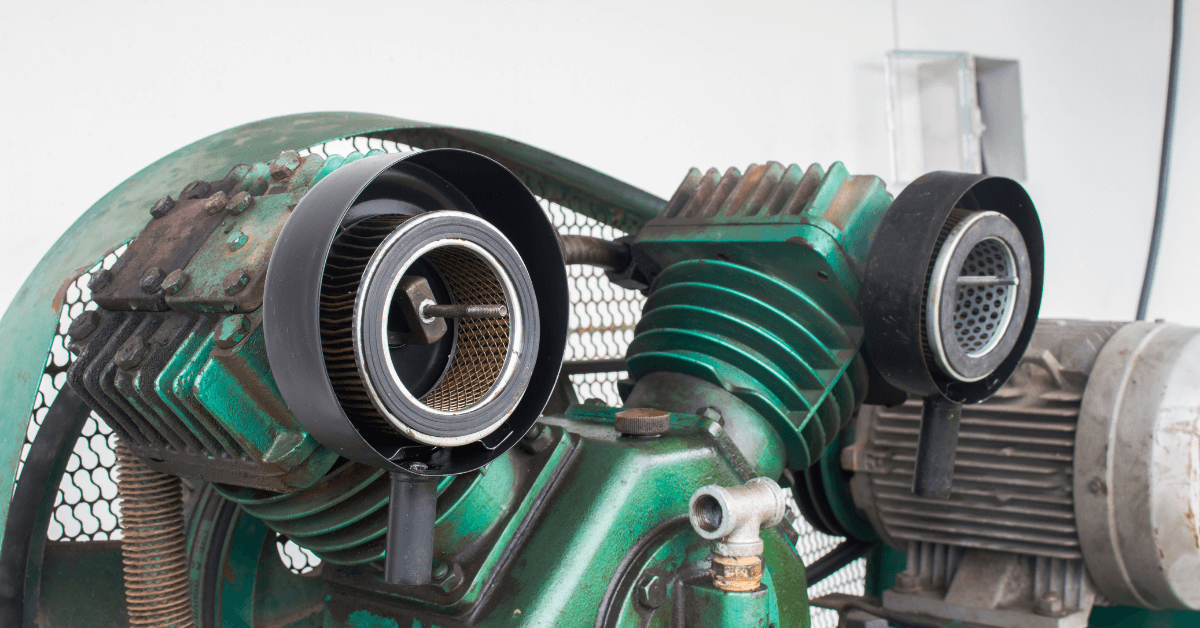

Image Source: outdoorhappens.com

An air compressor can be of varied size and shape. Hence there is always a need to make sure you choose the correct size that would suit your needs and needs as much as possible. The sizes are usually classified into:

Consumer grade compressors

Industrial air compressors

Professional grade compressors

Professional compressors are mostly used in small working areas and can be used to power the air tools. As for consumer-grade compressors, they are used for small and odd jobs such as inflation of tires or use of low-load air tools which include staplers.

If you need something that will last long, is hardy, and can be used continuously, then an industrial compressor is the right choice. Industrial air compressors are excellent for keeping the pressure steady.

b) 2-Stage Vs. Single Stage Compressors

The main difference between single and dual-stage compressors is the number of times that air gets compressed. In a single stage, the air is compressed only once and compressed twice in the dual stage. This is important to consider because a 2-stage compressor has more efficiency since they work less to produce compressed air.

Image Source: eatoncompressor.com

In a nutshell, your operating costs will be low with a two-stage compressor. Additionally, the intercooler stage allows for maximum cooling and decreases the chances of overheating. On the other hand, a single-stage compressor delivers maximum efficiency with uniform torque and better mechanical balance.

Single-stage air compressors are good for industrial uses like woodworking and auto-repair shops.

c) CFM Rating

The CFM rating refers to cubic feet per minute and indicates the amount of pressure you will achieve from your compressor per minute. If you need to run many tools at the same time, then you will need a higher CFM rating determined by the PSI range. At maximum pressure, your compressor should be producing enough high air pressure for your tools.

Image Source: machinelounge.com

It is crucial to note that some environmental factors negatively affect the CFM rating, including humidity and heat dissipation. However, there is nothing to worry about because your air tank will always deliver.

d) Features

Image Source: marineinsight.com

An air compressor is not a tool you will buy multiple times. A single compressor can last you more than 10 years, and therefore, you will be stuck with its features for a long time. Features make using the compressor easier. Here are some features to look out for in electric or gas compressors:

Ball valve drain; allows drainage from the air tank to avoid condensation.

Low oil monitoring device; notifies you when your oil is low.

Thermal protection; this can either be an automatic or manual thermal overload protection system that prevents damage to your unit in case of power interruptions.

Air cooling system; keeps your unit motor cool to prevent overheating.

Couplers; having many couplers on your unit will allow you to use multiple tools simultaneously.

Frequently Asked Questions About the Best 60-Gallon Air Compressors

i) Can you paint a car with a 60-gallon air compressor?

Yes, you can. A large 60-gallon tank will ensure you can coat an entire vehicle without needing a refill. Not to mention the pressure and variance of a large air compressor are steady.

ii) Is a 60-gallon air compressor enough?

Yes. Generally speaking, a 60-gallon tank should be enough for most jobs. It can power even the tools that require more air. Additionally, it can also power multiple tools simultaneously.

iii) How heavy is a 60-gallon compressor?

Keep in mind that a 60-gallon tank is not light by any means. The lightest 60-gal tanks weigh in at about 280 pounds.

iv) Can I lay my 60-gallon air compressor on its side?

That is not a good idea. If you lay the compressor on its side, it will go all the way down. Additionally, if the compressor is not portable types, then it is a wise idea to bolt it to the floor.

The Bottom Line

Compressors are some of the best helpers for powering pneumatic tools. Depending on how much pressure you need, 100 PSI is always a good starting point. Keep in mind that it is not hard to find a 60-gallon compressor that you like and whose features are perfect for you. Additionally, before settling on a compressor, ensure it is the one you want because compressors range in thousands of dollars.